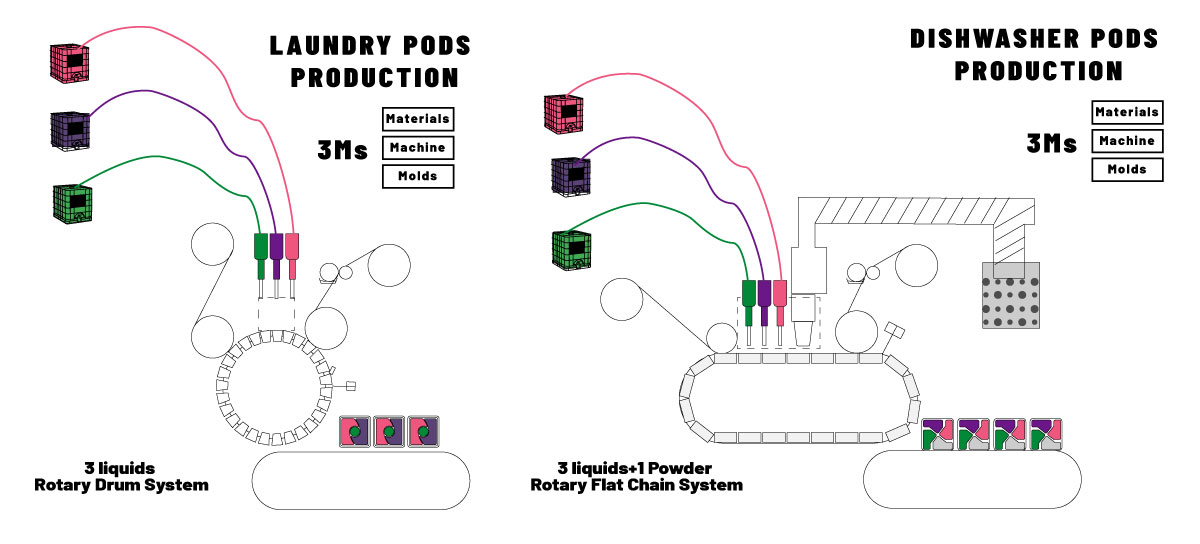

Why roatry chain

Advantages of a flat bed rotary chain system

Easy change over

compare to drum type machine, these new flat bed rotary type ones are much easier to change molds because of more working space.

Multi Steps Filling methods

New system allows to fill the materils in multi steps to form a product. By this advantage we are able to creat more complex prodcuts.

Multi Materils Flling capabilites

With more working space now we are not limited by the filling systems. It can gel, powder, liquid,or mix of all these forms.

Easy to use

Control by servos and more space for operator this new system are much easier to use than drums.

Higher fill rate

Since now the molds are moving on a very stable chain with no vabration or rotation.The liquid or powder can have a much higher fill rate.

Upgradable hardwear

Our industry changes all the time. If change molds can't solve problems we can still change the chains to be able to make new products

How the pods are made

Water soluble pods simple can be made by two layer of films. First layer of film being vacuumed down to a mold and form a chamber. Fill the chamber with materils and seal the second layer on the first one. Cut that off and it becomes a pod.

Redesign with Know Why

Laundry pods or we say water soluble pods ingenral are made by P&G with Clouds systems back in 2012. At that time the machine was designed to make pods to meet demands of P&G. But not all companies are like that huge.We provide solutions for a more flexible way to produce the pods with premium quality.

Higher production rate

With up to 14 rows filling capapcity the roatry chain system have the capability to make pods up to 1600 ppm. For complex products it will be your best choice.