A laundry detergent pod is a single-use, water-soluble packet containing highly concentrated cleaning agents, including detergent, stain removers, and brighteners. First popularized by Procter & Gamble's Tide Pods in 2012, they were designed to replace bulky liquid bottles and messy measuring cups with a "pop-in" solution.

In 2024, single-dose detergent pods accounted for approximately 24% of the retail market value makes it a major part of the cleaning business.

The rapid growth of laundry detergent pods in recent years has been driven primarily by evolving consumer lifestyles and a demand for convenience, efficiency, and sustainability. Today we going to dive a bit dipper in the product and finds out the science behind the scenes.

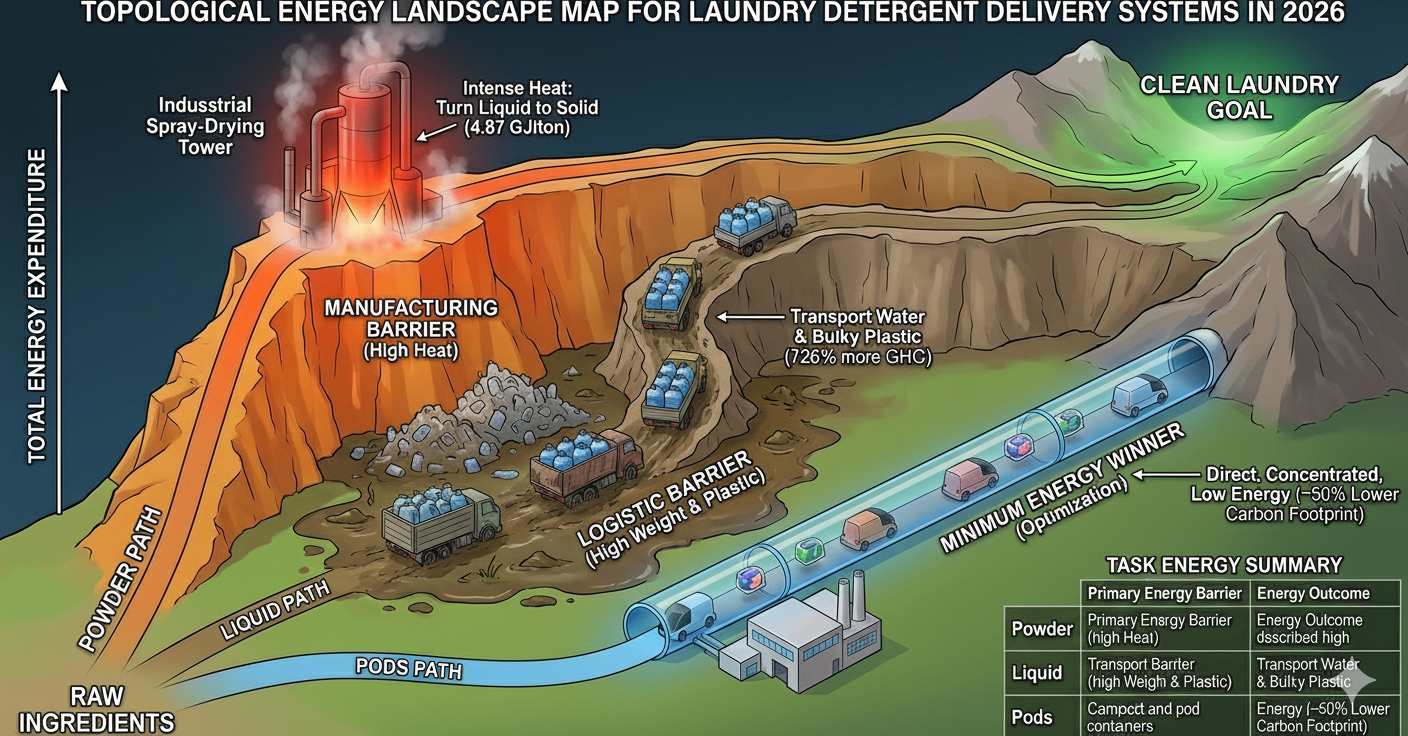

Based on Minimum Energy Path theory, the product that accomplishes a task with the least total energy expenditure is the natural "winner" in the market. In the detergent industry, the most efficient "delivery system" for chemicals from the factory to the home will ultimately dominate.

Here is a refined analysis of why laundry pods are the most energy-efficient format compared to powder and liquid:

1. The Energy Penalty of Powder (Manufacturing)

While powder is efficient to ship, it is energy-intensive to create. A primary cleaning agent, LAS (Linear Alkylbenzene Sulfonate), starts as a liquid. To transform it into a powder, manufacturers must neutralize it with caustic soda and then use high-heat spray-drying towers. This phase consumes a massive amount of energy just to change the chemical's physical state from liquid to solid.

2. The Energy Penalty of Liquid (Logistics)

Liquid detergent is the easiest to manufacture—simply mixing chemicals into water. However, the energy cost is hidden in logistics.

Water Weight: Standard liquids are 75–85% water, meaning most of the fuel used in shipping is spent moving water rather than active cleaning agents.

Plastic Waste: Liquid detergent requires heavy-duty plastic bottles made from petroleum. The energy required to refine the oil, mold the plastic, and transport the bulky empty containers is significant, and these bottles are often discarded after a single use.

3. The Efficiency of Pods (The Minimum Energy Path)

Laundry pods represent a "smarter" delivery system because they minimize energy consumption at both the factory and during transport:

Low-Energy Manufacturing: Unlike powder, pods do not require high-heat spray drying. Liquid ingredients are mixed in tanks, and solid/powder ingredients are processed in simple ribbon mixers. These two formats are then combined directly into a water-soluble film.

Concentrated Delivery: Pods contain highly concentrated surfactants and solvents with very little water. This drastically reduces the size and weight of the product, requiring significantly less fuel for delivery from the factory to your home.

Compatibility: Multi-chamber pods allow incompatible chemicals (like powders and liquids) to coexist in one unit without reacting prematurely. This eliminates the need to chemically "force" ingredients into a single liquid or powder state.

Conclusion

When we calculate the energy spent on chemical transformation (Powder) versus the energy spent on transporting water and plastic (Liquid), Pods emerge as the winner. They deliver the same high-quality cleaning chemistry to the consumer with the lowest total energy footprint. Translate the energy to our world language it’s money spent on the cleaning.

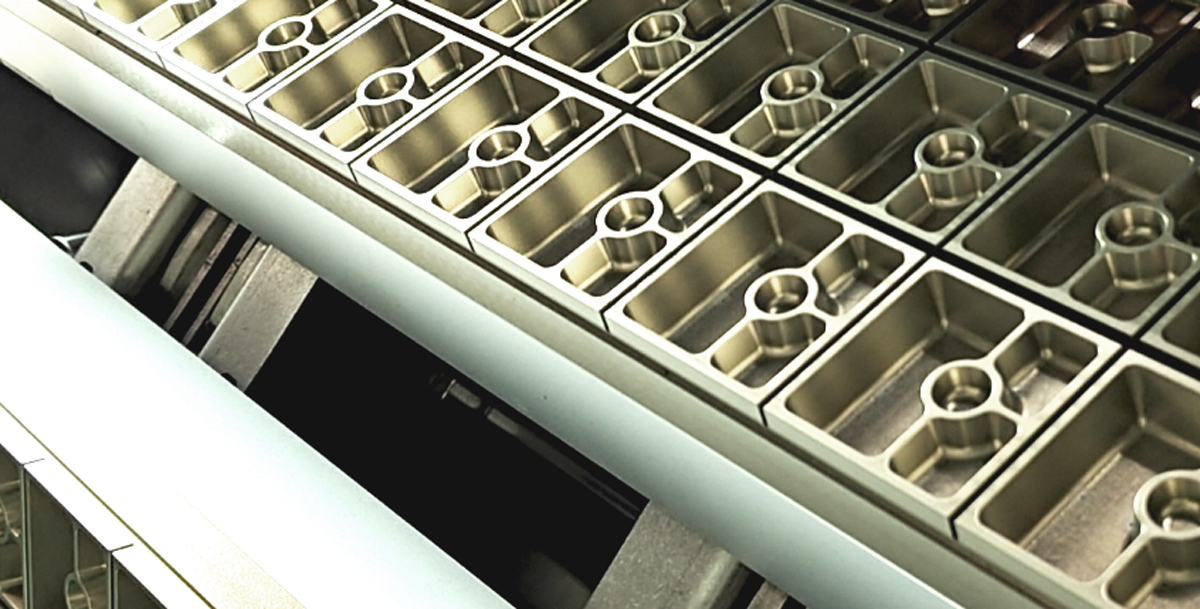

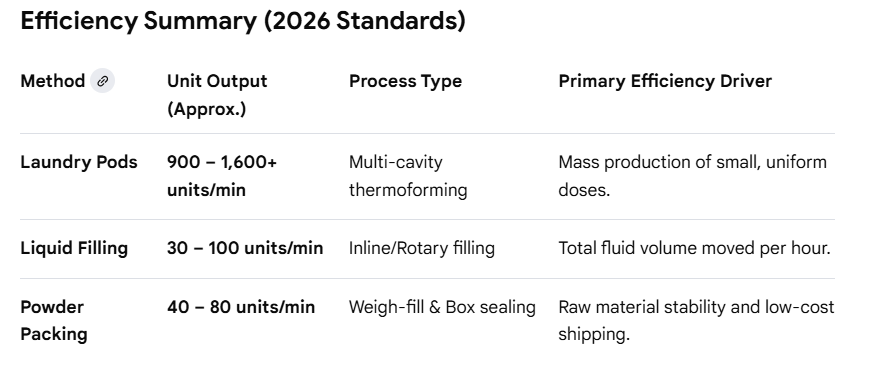

In 2026, the laundry detergent industry distinguishes production efficiency by comparing units per minute and volume per cycle. While laundry pod machines can reach speeds of up to 1,600 to 2,000 units per minute, this is significantly higher than traditional liquid or powder bottling lines.

The shift toward concentrated laundry pods has fundamentally changed detergent manufacturing by significantly reducing the physical footprint and material handling costs.

Because laundry pods use a highly concentrated, low-water formula, the industrial infrastructure required is much smaller:

Smaller Mixing Tanks: Standard liquid detergents can be up to 60%–80% water. In contrast, pods use ultra-concentrated formulas (sometimes 4x more concentrated than standard liquids), requiring significantly smaller mixing vessels and less energy for heating and blending.

Compact Equipment: High-speed pod machines occupy less floor space per unit of production than the combined infrastructure of a large-scale liquid bottling line or a massive powder spray-drying tower.

Lower Material Handling and Logistics Costs

The extreme concentration of the product leads to a lighter, smaller final unit, which optimizes the entire supply chain:

Weight Reduction: A box of 24 pods weighs approximately 600 grams, whereas a 5L bottle of traditional detergent—providing comparable cleaning power—weighs roughly 5 kg.

In-Plant Logistics: Smaller volumes of raw materials need to be moved through the factory, reducing the reliance on heavy machinery (forklifts/conveyors) and large storage silos for "filler" ingredients like water or bulk powder agents.

Shipping Efficiency: Because pods are compact and lightweight, manufacturers can fit significantly more "doses" into a single shipping container. This reduces fuel consumption, transportation costs, and the overall carbon footprint compared to shipping heavy, water-laden plastic jugs.

Strategic Storage Advantages

Warehouse Density: Pod packaging is generally compact and stackable. One pallet of laundry pods provides thousands more washes than a pallet of bulky liquid jugs, allowing manufacturers and retailers to maximize every square foot of storage space.

Stable Shelf Life: The separate chambers in modern pods (hybrid power-caps) keep ingredients like enzymes and oxygen bleach stable without them neutralizing each other, reducing the need for the complex stabilizers often required in high-volume liquid storage.

Shipping detergent pods for e-commerce can save a lot of money compared to traditional liquid detergents because pods are lighter, more compact, and contain less water. This directly translates to lower shipping costs, which are often determined by weight and dimensional size

All these advantages combined make pods the most significant technological advancement in the industry since the invention of synthetic detergents. The transformation of our cleaning industry has already begun—and it will spread like wildfire, unstoppable from one place to another.