Why Counting Pods

To Know exactly how many pods in the package.

Easy changeover with one click

With more working space now we are not limited by the filling systems. It can gel, powder, liquid,or mix of all these forms.

Power by AI Vision

Control by servos and more space for operator this new system are much easier to use than drums.

Self learning program

Our industry changes all the time. If change molds can't solve problems we can still change the chains to be able to make new products

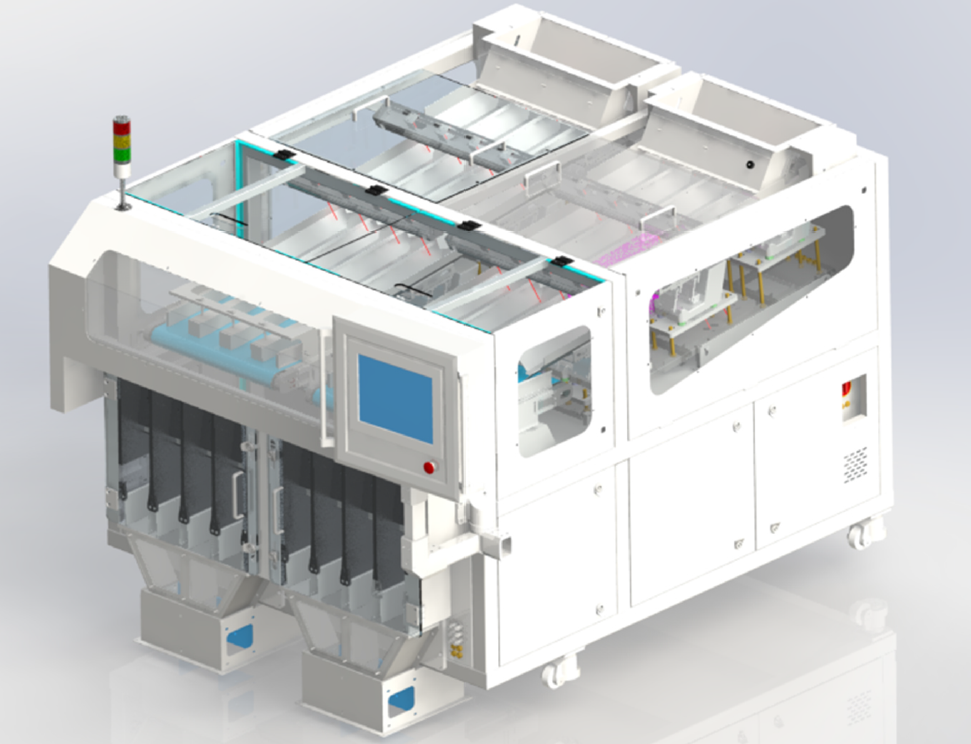

High Speed counting unit

compare to drum type machine, these new flat bed rotary type ones are much easier to change molds because of more working space.

Compatable with in/off line packing

New system allows to fill the materils in multi steps to form a product. By this advantage we are able to creat more complex prodcuts.

Higher accuracy

Since now the molds are moving on a very stable chain with no vabration or rotation.The liquid or powder can have a much higher fill rate.

How the pods are counts

Water soluble pods simple can be made by two layer of films. First layer of film being vacuumed down to a mold and form a chamber. Fill the chamber with materils and seal the second layer on the first one. Cut that off and it becomes a pod.

Redesign with Know Exactly How Many Pods

It's impossible to know exactly how many pods when the tolerance reach the weight of a pod. By Ai based vision couting system it can esnure you the custmers will be happy with the numbers.

Count with AI based Vision

With up to 8 channels of couting capacity the max speed of this unit can reach 750 pods per minute. With further extended group can double the speed.